Layanan Parts Mesin CNC Presisi Tinggi OEM

Layanan Mesin CNC

▪ Proses: CNC Turning, CNC Milling, Turn-mill Compound.

▪ Solusi Siji Mandeg Kanggo Mesin CNC.

▪ Parts Mekanik OEM, Parts Casting, Parts Machined, Parts CNC Custom, Prototype.

▪ Produsen Dhuwur Presisi.

▪ Panyedhiya Mesin CNC Kualitas Tinggi.

▪ Kustomisasi: Logo sing disesuaikan, Kemasan sing disesuaikan, Kustomisasi grafis.

▪ Bahan: Baja tahan karat, Aluminium, Baja Karbon, Tembaga, Kuningan, Paduan Baja, Titanium dll.

| Dhuwur Precision High Quality OEM CNC Machining Parts | |

| Layanan | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding |

| Bahan | Aluminium: 2000 seri, 6000 seri, 7075, 5052, etc. |

| Baja tahan karat: SUS303, SUS304, SS316, SS316L, 17-4PH, lsp. | |

| Baja: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Kuningan: 260, C360, H59, H60, H62, H63, H65, H68, H70, Perunggu, Tembaga | |

| Titanium: GradeF1-F5 | |

| Perawatan lumahing | Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nikel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Toleransi | +/-0,002~+/-0,005mm |

| Kekasaran lumahing | Min Ra0.1~3.2 |

| Drawing Ditampa | Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF, utawa Sampel |

| Lead Time | 1-2 minggu kanggo sampel, 3-4 minggu kanggo produksi massal |

| Jaminan Mutu | ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV |

| Syarat-syarat pembayaran | TT/ PayPal/ WestUnion |

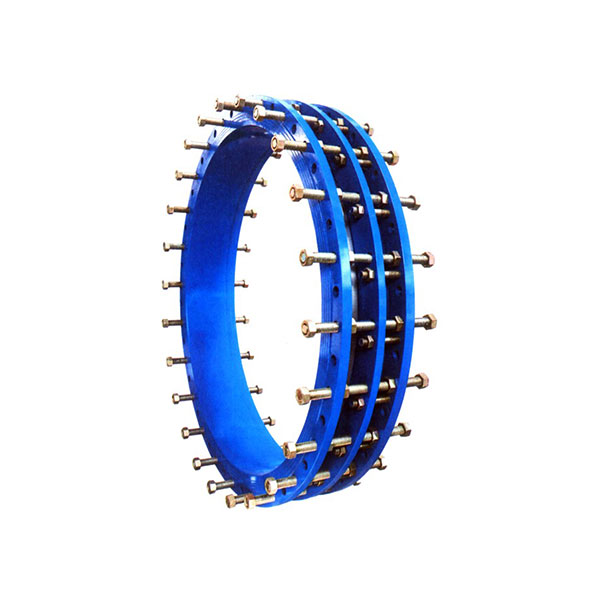

OEM CNC Machining High Precision High Quality Stainless Steel / Parts Steel

OEM CNC Machining High Quality Kuningan lan Titanium Parts

Kemasan Produk

FAQ

1. Apa CNC Machining?

CNC (Computer Numerical Control) minangka jinis manufaktur subtractive.Adhedhasar gambar, CNC nggunakake macem-macem alat kanggo ngethok bahan mentah kanthi program.

2. Apa bisa part sandi entuk manfaat saka CNC?

Dibandhingake karo cara manufaktur liyane, mesin CNC minangka cara serbaguna kanggo bahan, dimensi, produksi volume sing kurang.Iki njamin stabilitas, presisi, lan toleransi sing ketat.

3. Kepiye carane bisa njaluk penawaran?

Gambar rinci (PDF / STEP / IGS / DWG ...) karo materi, jumlah lan informasi perawatan permukaan.

4. Apa aku bisa njaluk penawaran tanpa gambar?

Manawa, kita seneng nampa conto, gambar utawa draf kanthi ukuran rinci kanggo kutipan sing akurat.

5. Apa gambarku bakal diungkapake yen sampeyan entuk manfaat?

Ora, kita mbayar manungsa waé akeh kanggo nglindhungi privasi pelanggan saka gambar, tondo asto NDA uga ditampa yen perlu.

6. Apa sampeyan bisa nyedhiyani conto sadurunge produksi massal?

Manawa, ragad sampel dibutuhake, bakal bali nalika produksi massal yen bisa.

7. Kepiye babagan wektu timbal?

Umumé, 1-2 minggu kanggo conto, 3-4 minggu kanggo produksi massal.

8. Kepiye carane sampeyan ngontrol kualitas?

(1) Inspeksi material - Priksa permukaan materi lan ukuran kira-kira.

(2) Produksi inspeksi pisanan - Kanggo mesthekake ukuran kritis ing produksi massal.

(3) Inspeksi sampling - Priksa kualitas sadurunge dikirim menyang gudang.

(4) Inspeksi pra-pengiriman--100% dipriksa dening asisten QC sadurunge dikirim.

9. Apa sing bakal sampeyan tindakake yen kita nampa bagean kualitas miskin?

Mangga ngirim gambar, insinyur kita bakal nemokake solusi lan nggawe maneh kanggo sampeyan kanthi cepet.